Business Unit concept

"Innovative "3-less" processing of metal parts by merging the die knowhow with high-speed composite fabrication"

Introduction of technical products

Hyper composite processing

Innovative processing of metal parts by achieving the "3-less"

Dieless

Parts-less

Collaboration of special dies with composite fabrication I: Combining two parts into one

Process-less

Collaboration of special dies with composite fabrication II: Combining two processes into one

Steel Material Business Unit information

Business details

Sheet metal working and processing and sale of steel materials

Products

* Composite fabrication parts: up to 3.2 mm

* Laser processed parts: up to 19 mm in thickness

* Commissioned processing of coils

* Sale of steel materials

Sheet metal working

Punch Laser Combination machine (TRUMPF TC6000L)

A state-of-the-art combination machine capable of punching, laser processing and forming in a single clamp.

Equipped with an 8-stage material stocker to supply materials and a sheet master to suck and transport workpieces, this machine is able to operate for 24 hours, contributing to shorter delivery period.

* Clean cut processing

* Clean cut processing

As nitrogen gas is used as the standard assist gas, the cut surface is free from oxide layer and looks beautiful, unlike that of laser processing that uses oxygen gas.

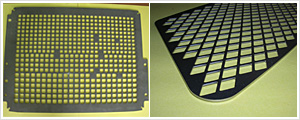

*High-speed, high-quality burr-less processing

*High-speed, high-quality burr-less processing

Burr and dross are a big problem affecting the subsequent processes.

Use of a high-speed, high-precision machine can alleviate this problem. Moreover, the small chamfering in the subsequent process can be integrated with the combination of a V-cut tool and a laser.

* Processing technology of combination machine

* Processing technology of combination machine

Punching that controls the warpage of the areas of small frame width

*Integration of the operations in the next process and elimination of dies by means of forming tools

*Integration of the operations in the next process and elimination of dies by means of forming tools

Laser machine (AMADA FO3015)

Able to cut sheet metals of up to 19 mm in thickness. Equipped with a 6-stage material stocker, this machine can operate 24 hours like the combination machine.

Able to cut sheet metals of up to 19 mm in thickness. Equipped with a 6-stage material stocker, this machine can operate 24 hours like the combination machine.

* Replacing cutting with laser processing

* Replacing cutting with laser processing

Since this machine is able to cut ordinary steel sheets of up to 19 mm in thickness, it can make flanges by cutting metal sheets instead of grinding round bars, thus reducing the number of processes.

* Gears

* Gears

Please specify the tooth number and depth as well as the shape of the gears you need. We will make them with gear fabrication software.

Commissioned processing and sale of steel materials

With large leveler and slitter lines, we function as a coil center and are engaged in the sale and commissioned processing of steel materials.

With large leveler and slitter lines, we function as a coil center and are engaged in the sale and commissioned processing of steel materials.

Items handled:/ Cold-rolled steel sheets, pickled steel sheets, high tensile steel sheets and surface treated steel sheets

Suppliers:/ Kobe Steel, Nisshin Steel and Tokyo Steel

* Leveling

* Leveling

Thickness: 0.4 mm – 2.3 mm

Coil width: 600 mm – 1250 mm

Minimum cutting length: 500 mm

We cut sheets to standard and other sizes as per customer requests.

We cut sheets to standard and other sizes as per customer requests.

* Slittering

* Slittering

Thickness: 0.4 mm – 3.2 mm

Coil width: 500 mm – 1300 mm

The number of strips depends on the thickness. See the slit number table.

The number of strips depends on the thickness. See the slit number table.

>>Click here for slit number table.